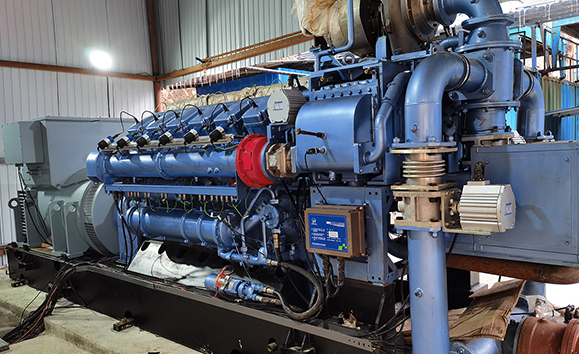

A coal mine in Shanxi uses high-temperature hot air from gas oxidation to produce saturated steam, supplying heated air to wellheads to prevent freezing.

Total gas processed: 2,100 Nm³/h of pure methane.

Steam output: 20 t/h.

Phase I: Covers 350 m², processes 420 Nm³/h of pure methane, and generates 4 t/h of steam.

Annual savings during the heating season: At least 1.2096 million cubic meters of natural gas.

CO₂emission reduction: 16,300 tons per heating season (120-day heating period).

Project timeline: From equipment installation to commissioning completion, completed in just 20 days.

Case

Case

Tel:13561083201

Tel:13561083201 Email:sales@comeriver.net

Email:sales@comeriver.net Fax:029-89690159

Fax:029-89690159 Add:No. A19, SI-Park Phase II, Nan’er Road, Dongying District (High-Tech Zone), Shandong Province, China, 257000 / No.1, Tai’ er Zhuang Road, Dongying District, Dongying City, Shandong Province, China

Add:No. A19, SI-Park Phase II, Nan’er Road, Dongying District (High-Tech Zone), Shandong Province, China, 257000 / No.1, Tai’ er Zhuang Road, Dongying District, Dongying City, Shandong Province, China